About the Battery Development Market

In conjunction with OXIS Energy and number of other companies, we are part of the Faraday Battery Challenge; which involves the UK government investing £246 million to support the development of new battery technologies.

It funds research, innovation and scale-up facilities for batteries for the electrification of future vehicles and other applications that support an electrified economy.

OXIS Energy is leading the Lithium Sulfur Future Automotive (LiSFAB) development project; to develop a next generation battery cell and module that will have the significantly improved power and cycle life required by heavy transport applications.

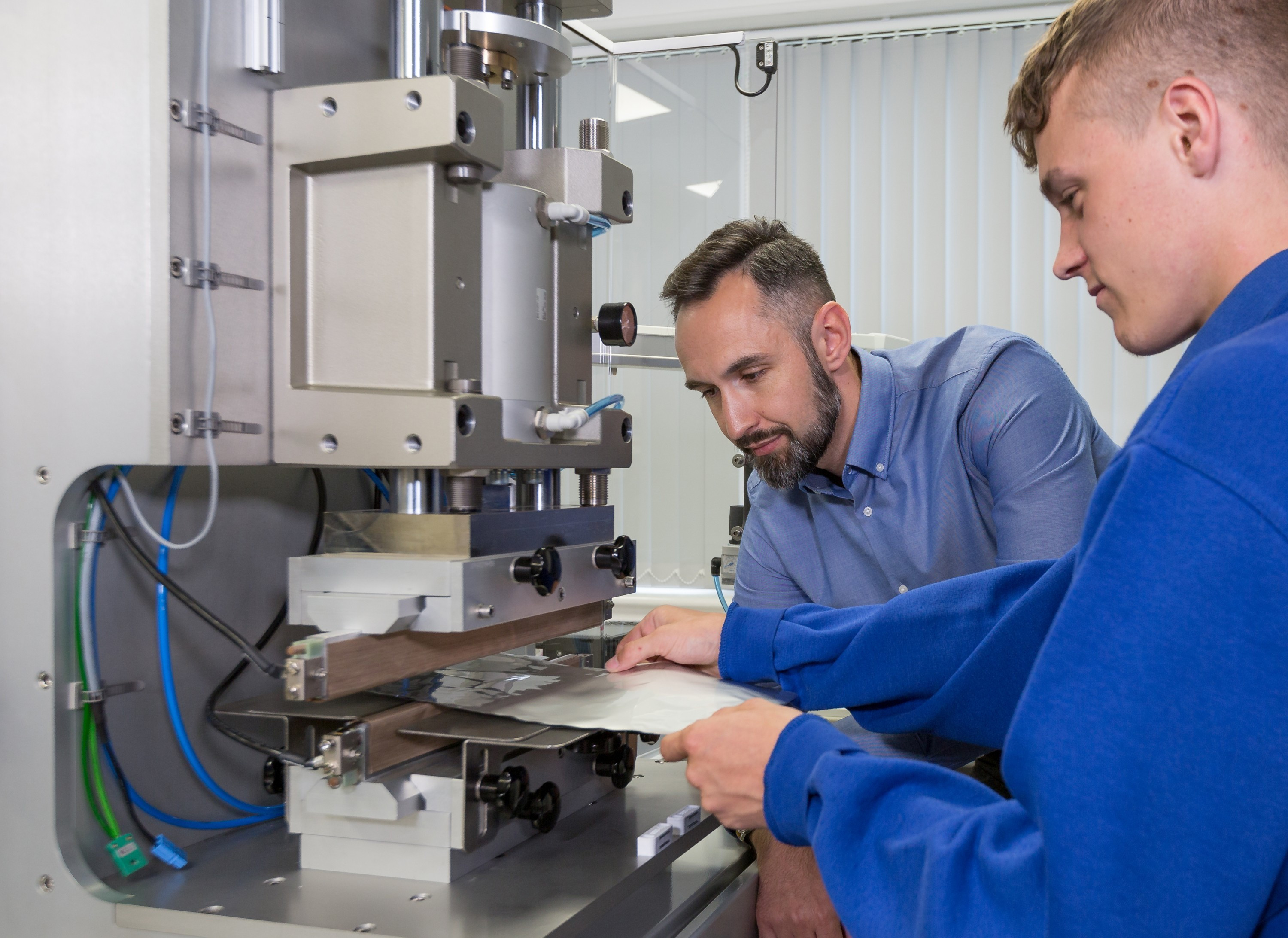

At our in-house test and development facility, our engineers have designed and built a dedicated test station to trial our key heat sealing technologies on the delicate materials and components involved in the assembly of the battery cells. To determine the best method of sealing, they ran extensive trials to validate the most robust and suitable process for final production.

When the high energy, lightweight battery cells reach the final production stage, the opportunities to reduce costs and emissions within the aviation, defence and automotive sectors will be countless.

Our Products

We have an extensive range of key heat sealing technologies that can be adapted to your individual application requirements.