Features

Rapid heat up and cool down, up to 2500mm long sealing

Precise temperature control for high integrity seals

Low maintenance and operating costs

Improved productivity, aesthetics and repeatability

What is it?

Our ImPulse Heat (IPH) sealing technology is particularly suitable for polyethylene material sealing but can be used with any heat seal material application.

How does it work?

The IPH sealing system consists of a seal bar, a temperature controller and all necessary power supply consumables supplied specifically to your application requirements. Within our IPH sealing system, precise tension for accurate sealing is maintained with the use of element expansion compensators.

We can supply our ImPulse Heat sealing systems with transverse tools such as cutters, air blast cooling, water cooling or different sealing profile formats depending on each individual application requirement.

A wide range of IPH sealing technologies are available from the basic seal jaw, to complete jaw sets mounted within a module.

Suitable for:

Our IPH sealing technology is suitable for the following materials: polyethylene, polypropylene, polystyrene, polyester, polyvinylchloride, laminate, biodegradable and compostable films.

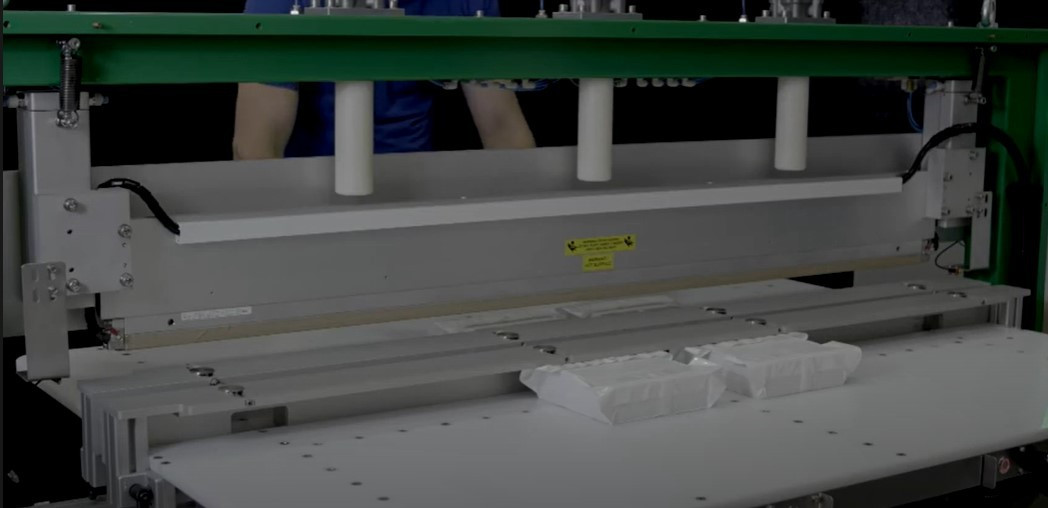

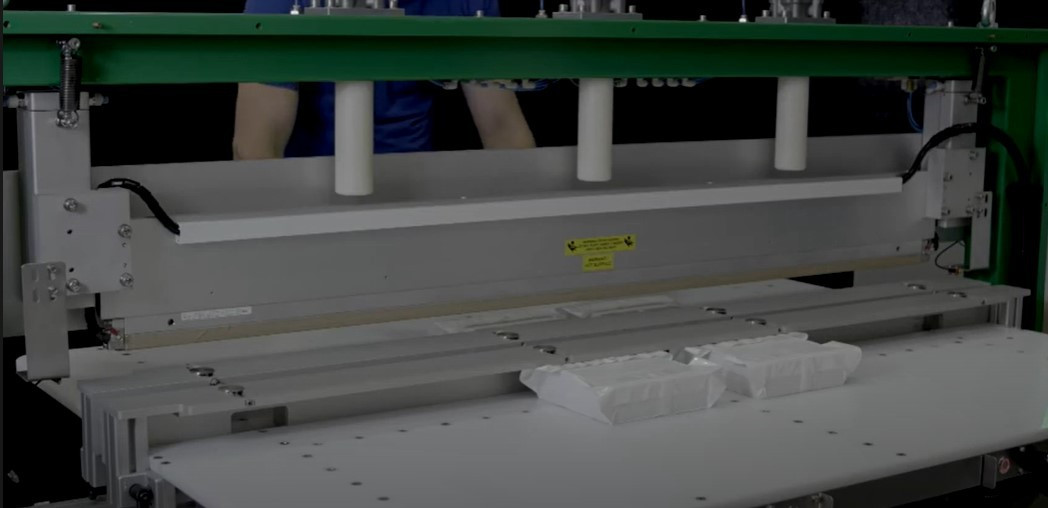

Our ImPulse Heat (IPH) technology in action, designed into a bespoke machine.