Complete design and build service

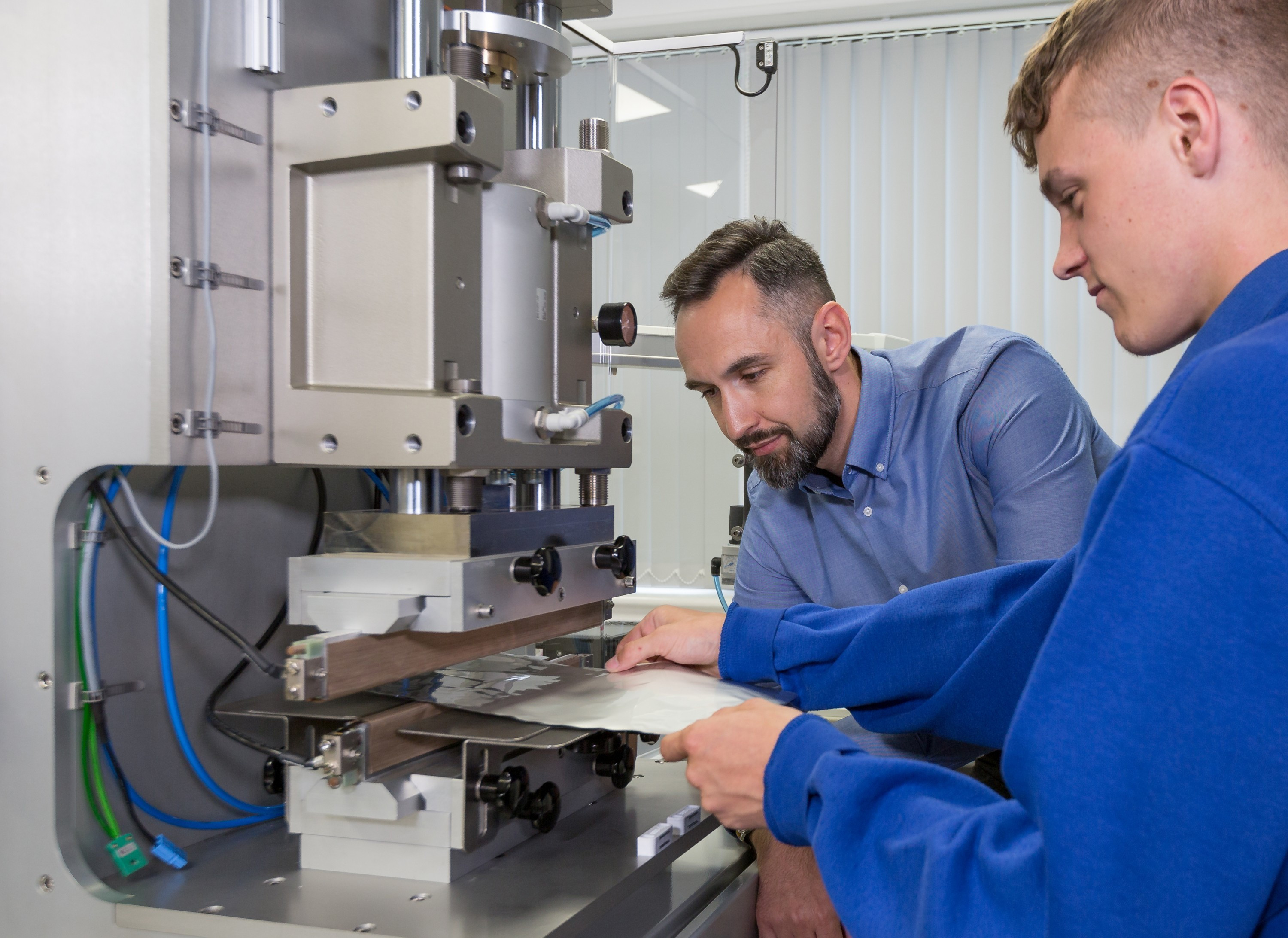

We provide a complete design and build service to enable our customers to fulfil their most challenging heat sealing requirements.

With over 30 years of heat sealing experience, our mechanical and electrical engineers are able to find the most suitable and economical solution for each individual application.

Alongside our extensive testing and development equipment and facilities, our engineers use the latest developments in 2D/3D CAD technology and FEA simulation software when formulating a design.

Using our individual heat seal technologies, we design and build complete machine solutions to replace our customer’s existing equipment and streamline production.

We can also design and build smaller heat sealing technology modules to be retrofitted onto our customer’s production lines.

In order to maintain the highest levels of product integrity, from design to manufacturing, we are ISO9001:2015, ISO14001:2015 approved.

We design, manufacture and install freestanding and bench top machines – both manual and automated if required.

Our bespoke machine builds can incorporate our customers own validation devices and equipment for proving temperature and forces applied.

Our engineers offer both onsite and in-house technical support for even the most challenging applications, assisting our customers across all industry sectors.

Our manufacturing processes

Our machines and components are manufactured in powder coated steel, stainless steel, anodised aluminium, composites and acrylics depending on the use and the user environment.

All of our bespoke machine builds can be integrated with Human Machine Interface (HMI) technology, PLC controllers, film control systems and PID digital temperature controllers.

All of our machines and heat sealing technology modules are designed to meet stringent safety regulations and are integrated with safety control system, designed in accordance with EC Directives and are supplied with a full suite of parts and operations manuals.

Risk Assessments are mandatory on all systems with FAT (Factory Acceptance Testing) incorporated within the project management process.

Servicing, support and spare parts

With any retrofit project or bespoke machinery build our engineers provide complete installation and training support to our customers in order to maintain a streamlined process when converting to our heat sealing technologies.

Our service engineers are on hand for off site support with software, systems and troubleshooting for our heat sealing technologies. We also provide a 24 hour call out service for on site support should customers require it.

We provide a complete spare parts sales service after installation of our equipment with original manufacture parts.

Product Range

We have an extensive range of key heat sealing technologies that can be adapted to your individual application requirements.